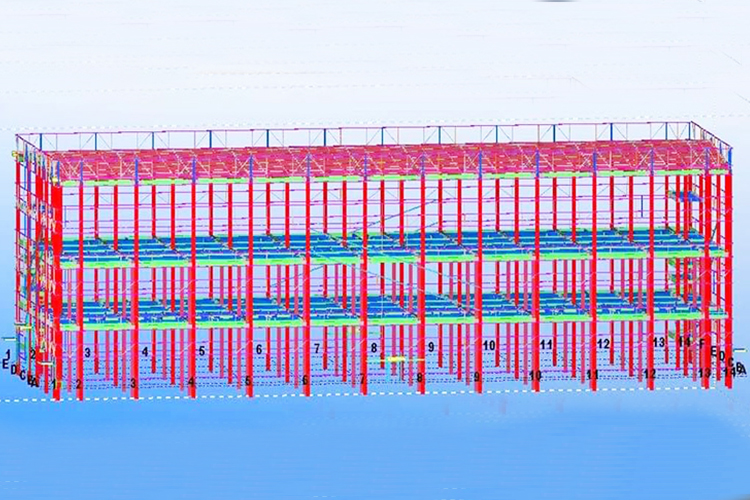

Steel Structure Workshop

The prefabricated steel structure workshop essentially comprises of several components, including steel columns, steel beams, steel structure foundations, steel roof trusses, steel roofs, steel structure walls, among other parts. The walls can also be enclosed with brick walls to suit individual needs. The span of the factory building is relatively large; thus, steel structure roof trusses are the go-to option for most builders.

| Structure | Description |

| Steel grade | Q235 or Q345 steel |

| Main structure | welded H section beam and column,etc. |

| Surface treatment | Painted or galvanzied |

| Connection | Weld,bolt,rivit,etc. |

| Roof panel | Steel sheet and sandwich panel for choice |

| Wall panel | Steel sheet and sandwich panel for choice |

| Packaging | steel pallet,wood box.etc. |

One of the primary benefits of prefabricated steel structure workshop is its light-weight nature. The structure is constructed using steel, which has a high strength-to-weight ratio, making it an ideal construction material. This feature makes the structure suitable for areas with soft or loose soil conditions, which are typically hard to build on using traditional construction methods.

The use of steel structure for buildings also offers considerable cost savings. The construction period is relatively short compared to conventional methods, which can take years to complete. This significantly reduces the investment costs, and the prefabricated nature of the structure saves time and labor costs.

The prefabricated steel structure workshop is comprised of different steel parts, including steel beams, steel columns, and steel roofs. The steel columns are typically made of H-shaped or C-shaped steel, while the beams are primarily C-shaped steel or H-shaped steel, with the height of the intermediate area determined according to the beam's span. The Girts are typically C-shaped steel, while the roofing uses two different materials – monolithic tile or composite panels. The composite panels are composed of polyphenylene, rock wool, polyurethane sandwich panels. This helps to keep the structure warm in winter and cool in the summer and also provides sound insulation to keep the structure quiet.

Despite the numerous benefits of prefabricated steel structure workshop, it is not without its limitations. The structure has poor fire resistance and is not resistant to corrosion, and as such should not be used in areas with low temperatures. However, the building is easy to move, and its recyclability makes its disposal pollution-free.

In conclusion, the prefabricated steel structure workshop offers an innovative solution for modern construction. Its light-weight nature, time-saving, and cost-effective features make it an ideal choice for building industrial and civil facilities. Despite its limitations, more and more builders are opting for the prefabricated steel structure workshop as an efficient and effective way to build environmentally conscious and sustainable structures.