The characteristics of steel workshop

Better earthquake resistance performance

Prefab workshops are mostly sloping roofs. Therefore, the roof structure basically adopts the triangular roof truss made of H steel. After sealing the structural, form a very solid "plate rib structure system". This structure system has stronger seismic resistance and resistance to horizontal load, and is suitable for areas with seismic intensity of more than 8 degrees.

Better wind resistance performance

Section steel structure building has the advantages of light weight, high strength, good overall rigidity and strong deformation capacity. The self weight of the building is only one fifth of that of the brick concrete structure, which can resist the hurricane of 70 meters per second, so that life and property can be effectively protected.

Durability

The residential structure of light steel structure is composed of cold-formed thin-walled steel member system, and the steel bone is made of super anti-corrosion high-strength cold-rolled galvanized sheet, which effectively avoids the influence of corrosion of steel plate in the process of construction and use, and increases the service life of light steel members. The service life of the structure can reach 100 years.

Fast construction

All dry operation construction is not affected by environmental seasons. A building of about 300 square meters only needs 5 workers and 30 working days to complete the whole process from foundation to decoration.

Environmental protection

Materials can be 100% recycled, truly green and pollution-free.

Energy saving

All adopt high-efficiency and energy-saving walls, with good thermal insulation, heat insulation and sound insulation effects, which can reach the energy-saving standard of 50%.

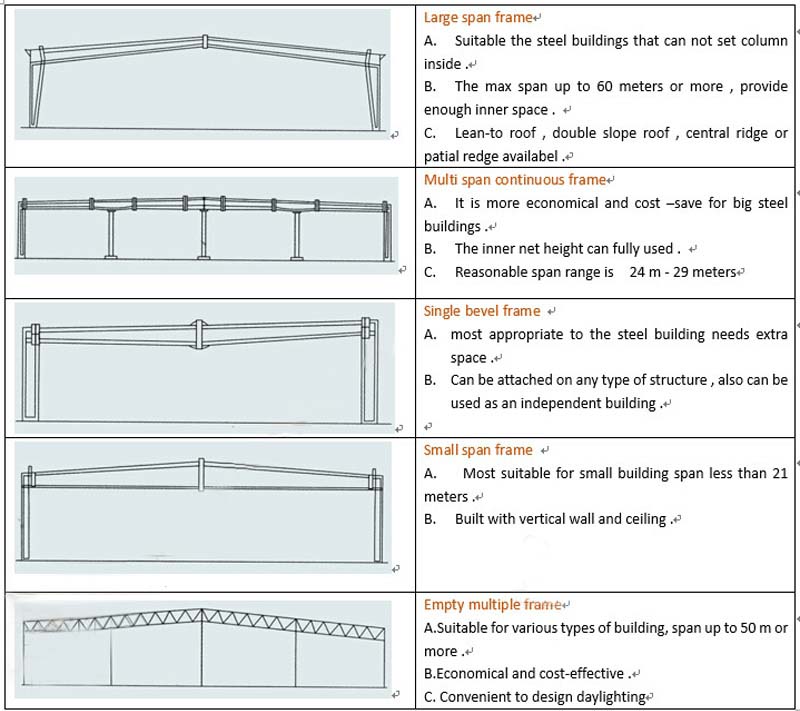

The types of steel structure workshop

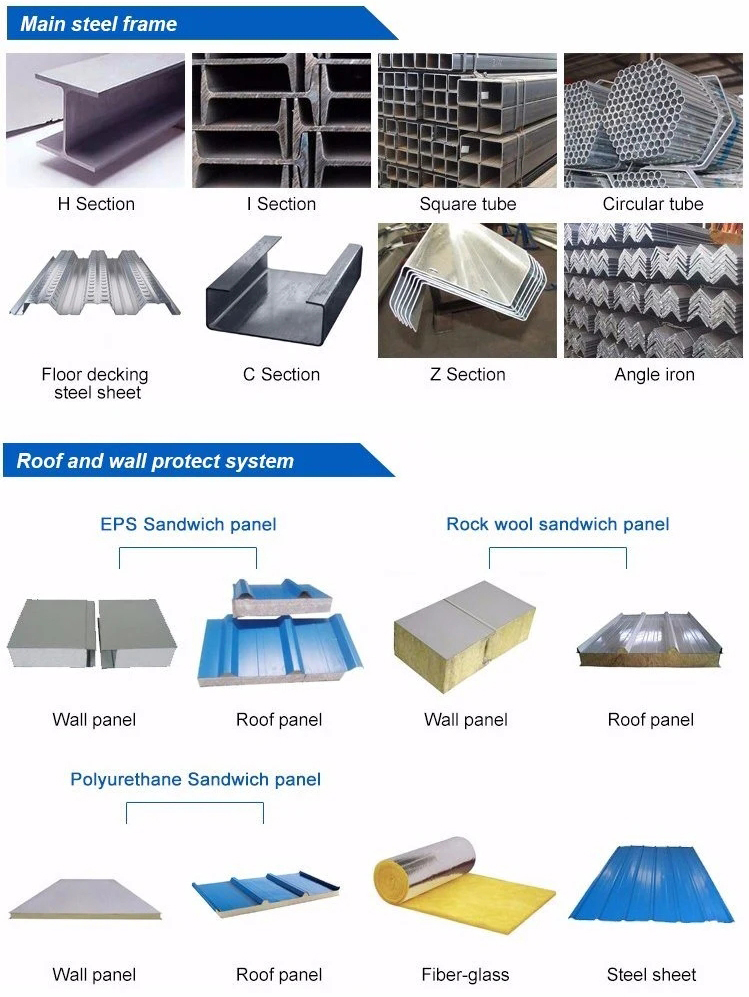

Main components

Embedded parts

It can stabilize the whole structure.

Column

Generally, H-shaped steel or C-shaped steel is used (usually two C-shaped steel are connected by angle steel)

Beam

C-section steel and H-section steel are generally used (the height of the middle area is determined according to the span of the beam)

Purlin

It is usually made of C-section steel and channel steel.

Cladding

There are two kinds. The first one is single tile (color steel tile). The second is composite board (polystyrene, rock wool, polyurethane). (foam is placed between the two layers of tiles to warm winter and cool summer, and also has the effect of sound insulation).

Finished projects