Steel Structure Factory

Steel factory buildings are one of the most common types of building structures in industrial and commercial environments. It is a prefabricated metal structure designed to provide businesses with convenience and affordability, while still providing the strength and durability needed to withstand harsh weather conditions. Steel structure factory buildings are more and more popular because of their high cost performance, convenient installation, strong versatility, and customization according to user needs.

| Structure | Description |

| Steel grade | Q235 or Q345 steel |

| Main structure | welded H section beam and column,etc. |

| Surface treatment | Painted or galvanzied |

| Connection | Weld,bolt,rivit,etc. |

| Roof panel | Steel sheet and sandwich panel for choice |

| Wall panel | Steel sheet and sandwich panel for choice |

| Packaging | steel pallet,wood box.etc. |

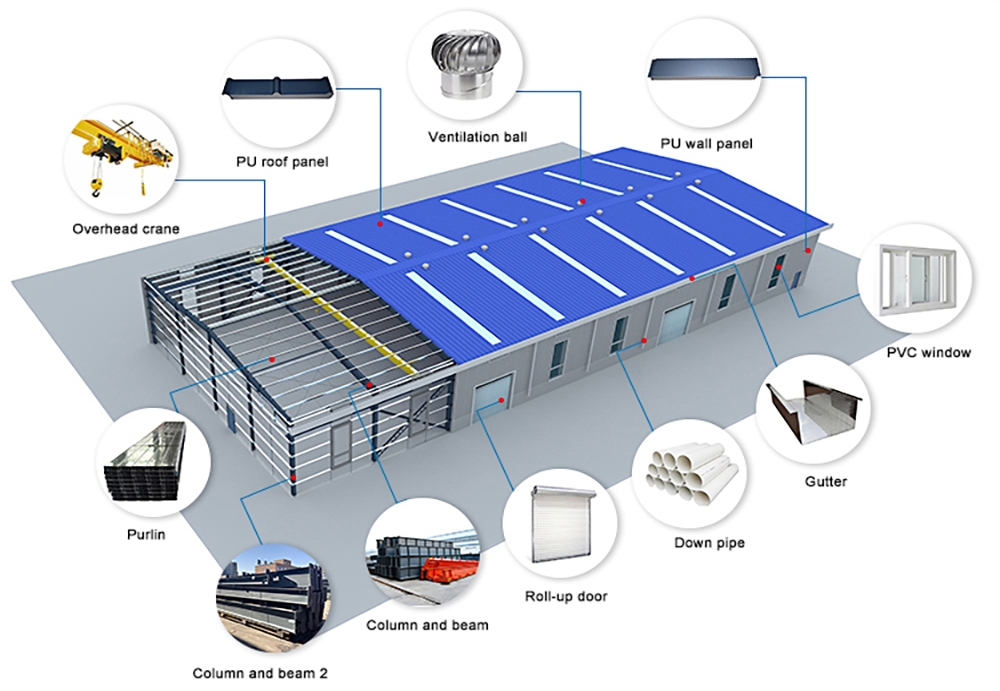

Steel Structure Factory Building Details

1. H section steel

H-shaped steel, also known as hot-rolled H-shaped steel, is a structural steel beam with an H-shaped cross section. It is commonly used in construction projects due to its excellent load-bearing capacity and durability. H-beams can be made from a variety of materials, including carbon steel, stainless steel, and aluminum, and come in a variety of sizes and thicknesses to suit different applications. The wide top and bottom flanges of H-beams also facilitate connection with other structural members.

2. C/Z section steel purlin

Steel purlins are structural members in a building's roof support system that extend horizontally from one truss to another. They are usually made of hot-rolled steel and come in a variety of sizes and specifications to accommodate different roof spans and load requirements. Steel purlins are installed perpendicular to the roof slope and usually support the roof tiles or cladding, as well as any insulation or other fixtures. They are an important part of a building's structural integrity, and proper installation and maintenance are critical to ensuring the long-term durability and stability of your roof system.

3. Support bracing

Braces refer to structural systems that provide additional support and stability to a building or structure. It may include materials such as steel cables or rebar, cross bracing or diagonal members designed to resist lateral forces such as wind or earthquakes. Bracing is commonly used in tall buildings, bridges and other structures exposed to high winds, seismic activity or heavy loads. The goal of bracing is to increase the overall strength and stability of the structure, reduce the risk of structural failure, and provide a safe and secure environment for its occupants.

4. Roof and wall

Roof and siding is a construction material primarily used to cover the exterior walls and roofs of buildings. They are available in a variety of materials such as metal, wood, vinyl and fiber cement and offer protection from external elements such as weather, wind and UV radiation. Roof and wall panels have the potential to improve the energy efficiency of buildings by providing better thermal insulation and also enhance the aesthetics of buildings due to their variety of colours, textures and finishes. The selection of roof and siding is usually based on the specific requirements of the building or project, such as location, budget and performance requirements.

5. Accessories

For steel buildings, accessories are an important part to help connect and fix different steel components. Some common structural steel fittings include bolts, nuts, washers, screws, anchors, brackets and plates. Made of high-quality steel, these fittings are designed to provide stability, strength and durability to the entire structure. They are also pre-engineered and pre-fabricated, making installation quicker and easier. Structural steel fittings are critical to ensuring that buildings can withstand a variety of weather conditions, including high winds, earthquakes and heavy snow loads.

6. Windows and doors

Selection of doors and windows of steel structure workshop: Aluminum alloy and plastic steel are preferred.

The Application Of Steel Structure Factory

The main applications of steel structure factory buildings include manufacturing plants (textile mills), warehouse/storage facilities (cold storage), offices (administrative centers), showrooms (retail stores), garages (auto shops), sports stadiums, etc. These spaces offer companies large and small an easy way to quickly scale their business without excessive investment in traditional brick-and-mortar infrastructure projects that often require significant upfront capital before any work can even begin! Also, thanks in no small part to its modular nature - many of the components associated with these types of workspaces can easily be pre-assembled off-site, speeding up setup times once everything arrives at your specific site .

Advantages Of Steel Structure Factory Building

Steel structures offer several advantages over other building materials. For starters, they're strong yet lightweight. This makes them ideal for use in areas with high winds or heavy snow, as they can easily carry a lot of weight without additional support from other structural elements such as walls or columns. Additionally, these workspaces require less maintenance than traditional buildings, as there are no exposed surfaces that need to be cleaned or painted regularly; this helps save on maintenance costs over time.

Another advantage associated with steel structures is their ability to resist fire; steel offers better fire protection compared to timber buildings due to their non-combustibility. Steel also has better sound insulation properties than most other materials, helping to reduce sound pollution in enclosed spaces, such as workshops or factories where machines run around the clock – which contributes to a healthier working environment overall !Finally, these structures are very versatile in terms of design options; customizable features such as height and door size can be adjusted accordingly, so users have more control over the look and function of their workspace according to their individual needs/requirements.

Overall - If you are looking for an efficient solution that fits your budget and your schedule, then a modern steel factory building is the way to go. Its sturdy construction will far exceed your expectations of any traditional building material, while its flexibility allows you to take full advantage of all the customization options available, ensuring that any project you choose will be done correctly - on the first try!