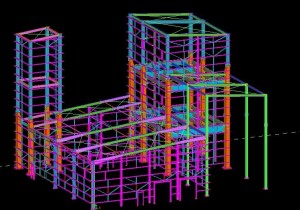

Steel Structure Workshop

A steel structure workshop building is crafted from steel. From the beams to the columns, these steel workshops are meant to provide a sturdy workshops, but without the costs of a traditional workshops. This type of infrastructure is more cost-effective and more lightweight, making them much easier to put up if you are in a hurry or you are on a budget.

Pre-engineered Steel Workshop Parameters

| Structure | Description |

| Steel grade | Q235 or Q345 steel |

| Main structure | welded H section beam and column,etc. |

| Surface treatment | Painted or galvanzied |

| Connection | Weld,bolt,rivit,etc. |

| Roof panel | Steel sheet and sandwich panel for choice |

| Wall panel | Steel sheet and sandwich panel for choice |

| Packaging | steel pallet,wood box.etc. |

1) Wind Resistance

Good rigidity and resistance to deformation make it resistant to 70 m/s hurricanes.

2) Shock Resistance

A strong “plate rib structure system” is suitable for areas where the seismic intensity is above 8 degrees.

3) Durability

The ultra-corrosion-resistant cold-rolled galvanized steel plate has a structural life of up to 100 years.

4) Insulation

Anti-cold-bridge, achieve thermal insulation effect.

5) Environmental Protection

The steel structure materials of the house can be 100% recycled.

6) Quick Construction

A building of about 6000 square meters can be basically installed in 40 working days.

The Application Of Steel Structure Workshop

Steel structure workshops are used in a wide variety of applications including industrial and commercial buildings,factory centers and factories. They offer the ability to build large structures quickly with minimal disruption to surrounding areas. In addition to providing efficient use of space and high levels of durability and strength, steel factory buildings can also be designed to increase energy efficiency by incorporating insulation in the wall or roof systems.

Features Of Steel Structure Workshop

A steel structure factory building is a building that can provide you with many advantages. Made of steel frame and cladding, it is very durable and strong.

Its construction process does not require complex techniques or tools, making it easy to assemble. In addition to strength, steel framing makes buildings more fire-resistant than other structures such as wood or brick buildings.

Additionally, steel structures are lightweight yet durable compared to traditional materials used in construction such as brick and concrete blocks. This makes them ideal for areas where strong winds or seismic activity can cause problems for traditional buildings.

Furthermore, since most components are prefabricated before delivery; they can be quickly assembled on site, significantly reducing labor costs during installation.With its superior quality and durability, steel structure factory buildings can provide you with great value for money while providing security against natural disasters such as earthquakes or hurricanes

Components Of Steel Structure Workshop

1. H section steel

H-section steel is commonly used to make steel beams and columns. H-section steel is common and most commonly used in steel structure engineering. H-section steel is named because its section is the same as the English letter "H" shape. Because H-beam is arranged at right angles in all parts, H-beam has the advantages of strong bending resistance, simple construction, cost saving and light weight in all directions and has been widely used.

2. C/Z section steel purlin

Purlins are usually made of C-and Z-shaped steel. C-shaped steel is automatically processed by C-shaped steel forming machine. Z-shaped steel is a common cold-formed thin-walled steel with a thickness of 1.6-3.0 mm and a section height of 120-350 mm. Horizontal components distributed along the length of the roof in steel structure are located on the main rafter, and purlin is the supporting secondary rafter.

3. The steel used for bracing, tie rod, corner bracing and support.

Tension, tie rod, support and corner support play an auxiliary role in supporting steel beams and columns. Angle steel, round steel and steel pipes are widely used.

4. Roof and wall

The roof and wall maintenance system can adopt metal steel sheet and sandwich panel. The thermal insulation effect of metal steel sheet is poor but the cost is lower. The thermal insulation effect of sandwich panel is better, and the cost is slightly higher than that of metal steel sheet.

5. Accessories

Parts bended with color plates, such as edge wrapping, angle wrapping, ridge tiles, etc. There are also some additional accessories, such as tapping nails, glue, rivets, etc.

6. Windows and doors

Selection of doors and windows of steel structure workshop: Aluminum alloy and plastic steel are preferred.

Why Choose Borton Steel Structure As Your Supplier?

We have been in business for more than 27 years and our products have been exported to more than 130 coumtries and regions.

In the field of steel structure construction, we are one of the professional custom manufacturer. We have our own factories,technicial team,construction,etc,will offer services from design, manufacturing to installation, our team has extensive experience handling various complex projects.

7 modern manufacturing plants,17 production lines, support us to provide the fastest delivery speed.

We provide custom design service, preliminary design is free.Of course,the surface treatment of steel structure,the material and color of roof and wall panel are up to you.If you have spealized requirements,we can also customize it for you.

From material preparation, cutting, assembly, welding, assembly to final spray drying, we have strict quality control in every step of production.The raw material should be from high quality factory,and we have advanced machines to make sure the profuction are in high-accuracy.

We have 7 modern steel structure manufacturing workshops and 20 production lines. Your order will not stay in the manufacturing facility for more than 35 days.

Professional And Warm Serives

We provide production process visualization (pictures and videos), shipment visualization, installation instructions. Our construction team consist of professional engineer and skilled workers will go to the site for guidance.Of course,we sincerely invite customers to visit our factory.