Frame Steel Structure

Multi-story frame steel structure building is a normal prefabricated building,which is widely used for high-rise civil buildings and multi-storey industrial factory due to the brick wall bearing can not meet the requirements of large load. They can better withstand the load from the weight of people, furniture, articles, mechanical equipment, floor slab, wall and self weight. The concrete wall only plays the role of enclosure and separation, and does not bear other loads except its own self weight. In order to reduce the load on the frame, light panels should be used as far as possible, such as foam concrete blocks (wallboards) or hollow bricks. Generally, most of the frames are cast on site. In order to accelerate the project progress and save the formwork and top bracing, partial prefabrication (such as column) and partial cast-in-situ (beam), or cast-in-situ construction of column beam precast joints can also be adopted.

| Building Size | Length X Width X Eave Height, According to Clients’ request | Application | Warehouse,office building,apartment,hotel,etc. |

| Type of Steel For Building Structure | H-Section Steel | Carbon Structural Steel | Q235,Q345 |

| Life Time | Up to 50 years | Certificate | CE,ISO |

| Origin | Qingdao,China | HS Code | 9406900090 |

| Main Frame | Hot Rolled or Built-up H Section, Q235B, Q345b | Secondary Frame | X/V Type Bracing, C/Z Purlin, Q235B |

| Surface Treatment | Painted or Galvanized | Roof & Wall | Single Sheet or Sandwich Panel |

| Foundation | Concrete Foundation and Steel Anchor Bolt | Connection | All Bolt Connection(High-Strength and Normal Bolt) |

| Window | PVC, Steel Plastic, Aluminium | Door | Floding Door, Lifting Door,Sliding Door, Roller Door |

| Installation | Engineer Helps to Instruct Installation | Transport Package | Standard Export Package or Customer′s Requirement |

The Advantages Of Frame Steel Structure

●Flexible space , light deadweight, as well as material saving;

●The frame steel structure has the advantages of flexibly matching with the building plane layout, and is favorable for arranging the building structures that need large space;

●The beam and column components of the frame structure are easy to be standardized and finalized, and it is easy to adopt the assembled integral structure to shorten the construction period;

●The integrity and rigidity of the structure are good, and the seismic effect can also be achieved after the design and treatment, and the beam or column can be poured into various required section shapes.

Material show

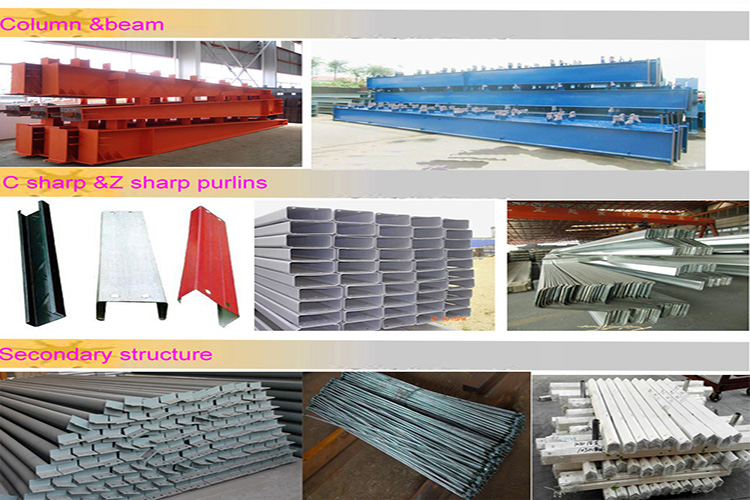

1.Main structure

A.The Main steel structure: Q355B Q345B Q235B H column /Beam /Second beam

B.Secondary Steel Structure: Q355B Q345B Q235B Square tube/ angle steel / circular tube etc

C.Purlin: Hot dipped galvanized C /Z section steel

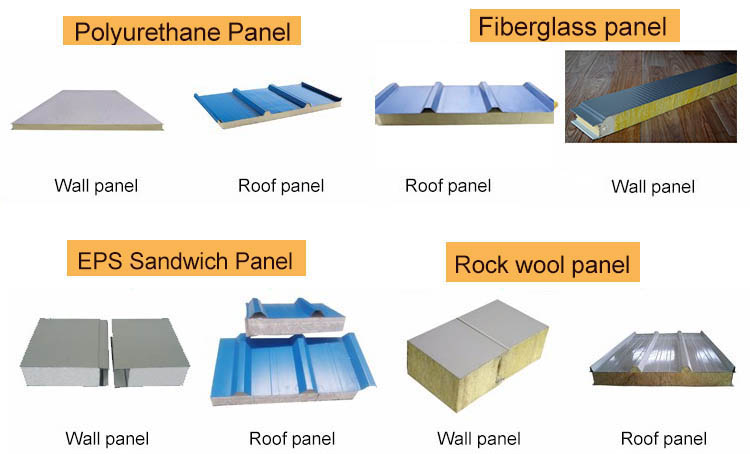

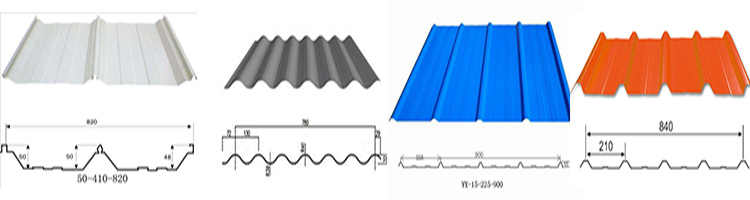

2.Cladding system

A.Corrugated steel sheet ,simple and most economic,is an ideal choice if want to finish the building in a lower cost.But it is not recommended if there are requirements for thermal insulation.

B.Sandwich Panel: EPS/ Rock wool/ Fiberglass /Polyurethane(PU) sandwich panel ,with good performance of fireproof,waterproof as well as thermal insulation.But the cost is higher than metal sheet.

C. Steel wire + steel sheet +Fiberglass /wool roll.This solution is also with good fireproof ,waterproof and thermal insulation ,the cost reduce much than sandwich panel,but need more time to install them on site

D.Aluminium panel +glass curtain.Nice appearance and good fireproof ,waterproof as well as thermal insulation,but the cost is higher than three solution above.

3.Bolt Accessories

A.Foundation Bolt

B.High-Strength Bolt

C.Ordinary Bolts

D.Other: Expansion bolt/ Self-tapping screw Embedded parts etc