Prefab Storage Shed

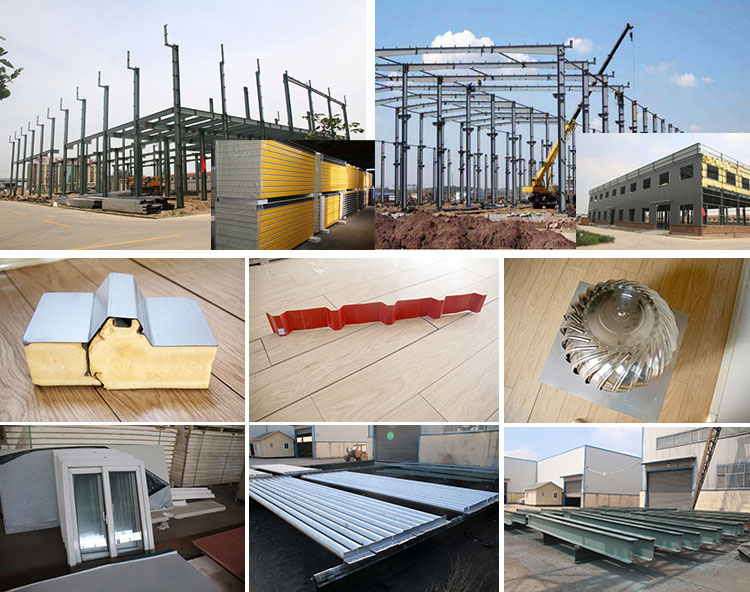

Prefab Steel Storage Sheds are simple prefabricated steel structure building,but sturdy and durable and can withstand high winds, snow, or earthquakes.They are always with H section steel or square tube for column and beam,roof and wall can be corrugated steel sheet or sandwich panel.They can be used for storage usage on farm or in factory,such buildings can be owned in an economic cost.

| Building Size | Length X Width X Eave Height, According to Clients’ request | Application | Farm shed,warehouse,workshop,garage,etc. |

| Type of Steel For Building Structure | H-Section Steel | Carbon Structural Steel | Q235,Q345 |

| Life Time | Up to 50 years | Certificate | CE,ISO |

| Origin | Qingdao,China | HS Code | 9406900090 |

| Main Frame | Hot Rolled or Built-up H Section, Q235B, Q345b | Secondary Frame | X/V Type Bracing, C/Z Purlin, Q235B |

| Surface Treatment | Painted or Galvanized | Roof & Wall | Single Sheet or Sandwich Panel |

| Foundation | Concrete Foundation and Steel Anchor Bolt | Connection | All Bolt Connection(High-Strength and Normal Bolt) |

| Window | PVC, Steel Plastic, Aluminium | Door | Floding Door, Lifting Door,Sliding Door, Roller Door |

| Installation | Engineer Helps to Instruct Installation | Transport Package | Standard Export Package or Customer′s Requirement |

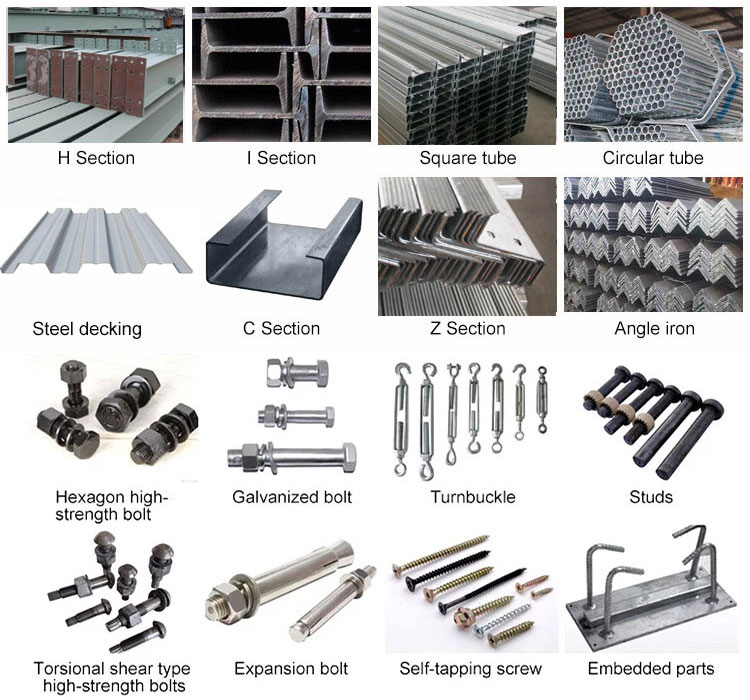

Material show

The main structure of building is mainly composed of steel beams, steel columns, steel trusses and other components made of section steel and steel plates. The components or parts are usually connected by welds, bolts or rivets.

The roof and wall cladding system mainly includes purlins, wall beams, roof and wall panel, etc. This system is the coat of the steel structure building. Its most basic function is to keep out the wind and rain, separate the space, and another is to decorate.Corrugated metal sheet is widely used for such prefab storage shed,of course as well as sandwich panel which has better performance of insulaiton.

How Is Steel Structure Finished In Factory

1. Using automated equipment - CNC flame cutting machine, the steel plate will be cut into main steel components

Advantages: 1> Accurate cutting, error±2mm; 2> High production efficiency, can cut 150-200 tons of plates a day;

2. Use automated equipment - CNC drilling machine for small parts production

Advantages: fast speed, high precision, deviation≤1mm, to ensure 100% installation error-free

3. Use automatic equipment--straightening and welding integrated machine, H-beam assembly, submerged arc welding, and straightening three processes into one

Advantages: The error of the finished product is +—2mm, and the finished product is produced about 25 meters per hour, which greatly improves production efficiency.

4. Use the section steel intelligent marking robot to mark the welding position of the four sides of the section steel and mark the component number

Advantages: high accuracy, can be temporarily or permanently marked. It replaces the manual measurement of the later assembly team, which improves the production efficiency of the later production process by more than 80%

5. Use the steel cutting robot for thermal cutting of H-beam, I-beam, etc.

Advantages: The error range is within 2mm; the cutting port is smooth and beautiful, which is convenient for the later welding of the welding port; the tedious process of artificial incision and post-grinding is omitted; the cutting efficiency is fast, and the output can reach up to 50T/day.

6. Assemble the connecting plate; perform local spot welding by electric welding; check the dimensions to ensure that the dimensions of each component conform to the drawings.

7. Solder all the connections in the assembly process

Advantages: high productivity in cross-operation with assembly process, fast welding efficiency

8. Shot blasting and derusting process

Through the impact and cutting action of the spray material on the profiled steel, the surface rust of the profiled steel is removed to increase the roughness, and manual slag removal treatment is also performed.

Advantages: very good preparation for painting, enhanced adhesion of the coating to the profiled steel, extended durability of the coating film

9. Spray paint

Spray paint according to the drawings and customer requirements, and spray 4 times. After completion, the surface of the component will not sag, no bubbles, no cracks, and the color is uniform and beautiful.

1.The primary and secondary steel are packaged as a whole;

2.The accompanying items are packed in boxes;

3.The roof, wall panels and accessories are packed in bulk;

4.Each part of all items is printed with an independent number, which is convenient for customers to install and use;

5.Adopt the most reasonable packing scheme to ensure the maximum use of the container's space load;

Installation On Site

Our own construciton team which consist of engineer and workers,have been to many countries to guide or finishe the installation of steel structure building.So,you needn't worry ahout the question of installation.

Contact Us For Design

We have professional designers who can provide you with free design solutions according to your requirements. So, if you have any needs, you can contact us at any time.