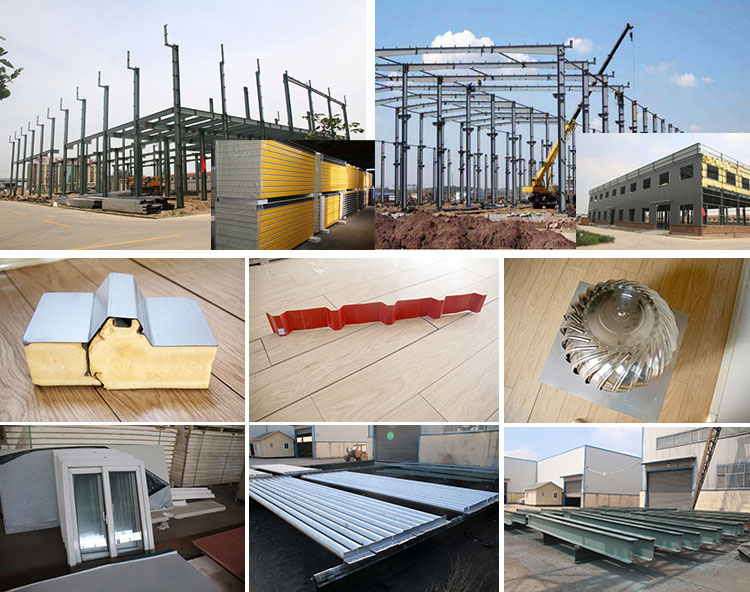

A steel warehouse is an ideal solution for your storage and management needs,a mezzanine can also be set up as an office on the second floor to meet office needs.It is usually composed of steel beam, steel column, steel purline,bracing,cladding. Each part connected by welds, bolts, or rivets.

But why even choose prefabricated steel structure warehousing as an option?

Steel warehouse vs traditional concrete warehouse

The major function of warehouse is to store goods, so ample space is the most important feature.The steel structure warehouse has a large span and a larger utilization area,which combines this feature.In recent years, more and more steel structure warehouse buildings are coming up, an indication that many entrepreneurs are abandoning the concrete structure construction model that has been used for many years.

Compared with traditional concrete warehouses,steel structure warehouses can save construction time and labor cost. The construction of the steel structure warehouse is rapid, and the response to sudden needs are apparent, which can meet the sudden storage needs of the enterprise.The cost of building a steel structure warehouse is 20% to 30% lower than a typical warehouse construction cost, and it is more secure and stable.

Steel structure warehouse has lightweight,And roof and wall are corrugated steel sheet or sandwich panel,which are much lighter than those in brick-concrete walls and terracotta roofs, which can effectively reduce the overall weight of the steel structure warehouse without compromising its structural stability. At the same time, it can also reduce the transportation cost of components formed by off-site migration.

Comparison between Pre-Engineered and Conventional Steel Building.

| Properties | Pre-Engineered Steel Building | Conventional Steel Building |

| Structural Weight | Pre-engineered buildings are on the average 30% lighter because of the efficient use of steel. Secondary members are light weight roll formed “Z” or “C” shaped members. |

Primary steel members are selected hot rolled “T” sections. Which are, in many segments of the members heavier than what is actually required by design. Secondary members are selected from standard hot rolled sections which are much heavier. |

| Design | Quick and efficient design since PEB’s are mainly formed by standard sections and connections design, time is significantly reduced. | Each conventional steel structure is designed from scratch with fewer design aids available to the engineer. |

| Construction Period | Average 6 to 8 weeks | Average 20 to 26 weeks |

| Foundation | Simple design, easy to construct and light weight. | Extensive, heavy foundation required. |

| Erection and Simplicity | Since the connection of compounds is standard the learning curve of erection for each subsequent project is faster. | The connections are normally complicated and differ from project to project resulting tin increasing the time for erection of the buildings. |

| Erection Time and Cost | The erection process is faster and much easier with very less requirement for equipment | Typically, conventional steel buildings are 20% more expensive than PEB in most of the cases, the erection costs and time are not estimated accurately. Erection process is slow and extensive field labour is required. Heavy equipment is also needed. |

| Seismic Reistance | The low weight flexible frames offer higher resistance to seismic forces. | Rigid heavy frames do not perform well in seismic zones. |

| Over all Cost | Price per square meter may be as low as by 30 % than the conventional building. | Higher price per square meter. |

| Architecture | Outstanding architectural design can be achieved at low cost using standard architectural details and interfaces. | Special architectural design and features must be developed for each project which often requires research and thus resulting in higher cost. |

| Future Expansion | Future expansion is very easy and simple. | Future expansion is most tedious and more costly. |

| Safety and Responsibility | Single source of responsibility is there because the entire job is being done by one supplier. | Multiple responsibilities can result in question of who is responsible when the components do not fit in properly, insufficient material is supplied or parts fail to perform particularly at the supplier/contractor interface. |

| Performance | All components have been specified and designed specially to act together as a system for maximum efficiency, precise fir and peak performance in the field. | Components are custom designed for a specific application on a specific job. Design and detailing errors are possible when assembling the diverse components into unique buildings. |

Excellent load-bearing design

Load-bearing capacity should be considered when design,to ensure the steel warehouse can withstand rainwater, snow pressure, construction load, and maintenance load.What more,must meet the requirements of functional bearing capacity, material strength, thickness and force transmission mode, bearing capacity, cross-section characteristics of the version, etc.

The load-bearing problems of the steel structure warehouse design need to be well-considered to reduce the warehouse’s damage capacity,to achieve a longer service life.

Energy efficiency design

If traditional concrete warehouse or wooden warehouse,light should be turned on all day and night,which will undoubtedly an increase in energy consumption. but for steel warehouse,there will be the need to design and arrange lighting panels at specific locations on the metal roof or installing lighting glass, using natural light where possible, and doing waterproof work at the same time to maximize the service life.

The major components of the PESB are divided into 4 types-

Primary components of the PESB consists of mainframe, column, and rafters-

The main framing basically includes the rigid steel frames of the building. The PESB rigid frame comprises of tapered columns and tapered rafters. Flanges shall be connected to webs by means of a continuous fillet weld on one side.

The main purpose of the columns is to transfer the vertical loads to the foundations. In pre-engineered buildings, columns are made up of I sections which are most economical than others. The width and breadth will go on increasing from bottom to top of the column.

A rafter is one of a series of sloped structural members (beams) that extend from the ridge or hip to the wall-plate, downslope perimeter or eave, and that are designed to support the roof deck and its associated loads.

Purlins, Grits and Eave struts are secondary structural members used as support to walls and roof panels.

Purlins are used on the roof; Grits are used on the walls and Eave struts are used at the intersection of the sidewall and the roof. Purlins and girts shall be cold-formed "Z" sections with stiffened flanges.

Eave struts shall be unequal flange cold-formed "C" sections. Eave struts are 200 mm deep with a 104 mm wide top flange, a 118 mm wide bottom flange, both are formed parallel to the roof slope. Each flange has a 24 mm stiffener lip.

Cable bracing is a primary member that ensures the stability of the building against forces in the longitudinal direction such as wind, cranes, and earthquakes. Diagonal bracing in the roof and side walls shall be used.

The sheets used in the construction of pre-engineered buildings are Base metal of either Galvalume coated steel conforming to ASTM A 792 M grade 345B or aluminum conforming to ASTM B 209M which is cold-rolled steel, high tensile 550 MPA yield stress, with hot dip metallic coating of Galvalume sheet.

Non-structural parts of the buildings such as bolts, turbo ventilators, skylights, lovers, doors and windows, roof curbs and fasteners make the accessories components of the pre-engineered steel building.

Installation

We will provide customers with installation drawings and videos. If necessary, we can also send engineers to guide the installation. And, ready to answer related questions for customers at any time.

In the past time,our construction team have been to many countries and region to accomplish the installation of warehouse ,steel workshop,industrial plant,showroom,office building and so on.The rich experience will help customers save much money and time.