H-section steel is a kind of economic section and high-efficiency section with more optimized cross-sectional area distribution and more reasonable strength-to-weight ratio. It is named because its section is the same as the English letter "H". Since the various parts of the H-shaped steel are arranged at right angles, the H-shaped steel has the advantages of strong bending resistance, simple construction, cost saving and light structure weight in all directions.

H steel is mainly used for beam and column members in industrial and civil structures,steel structure bearing supports for industrial structures Steel piles and supporting structures for underground projects, large-span steel bridge components for industrial equipment structures such as petrochemicals and electric power. Ships, machinery manufacturing frame structures, trains, automobiles, tractors, and tractor beam supports, port conveyor belts, high-speed baffles Bracket.

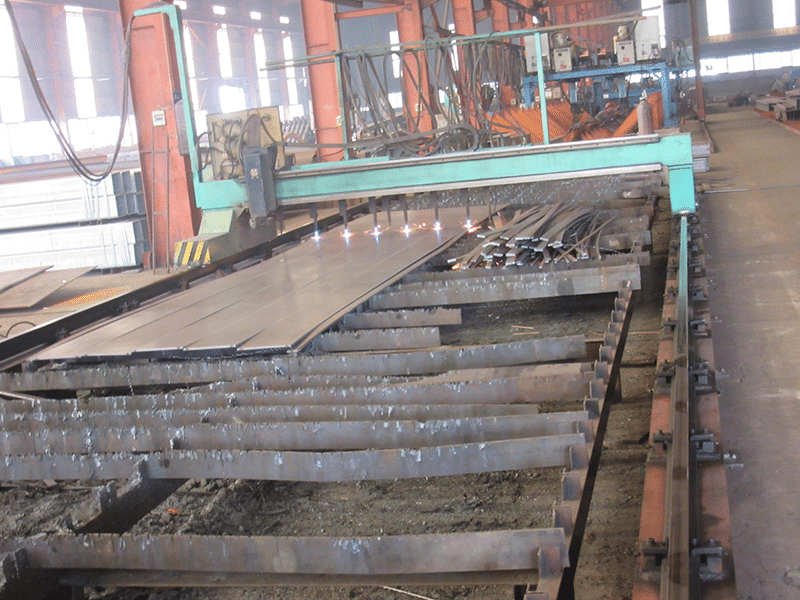

Step 1 Blanking

Checking specifications,quality and appearance of raw material,then cutting steel plate into sizes required by Numerical Control Cutting Machine.

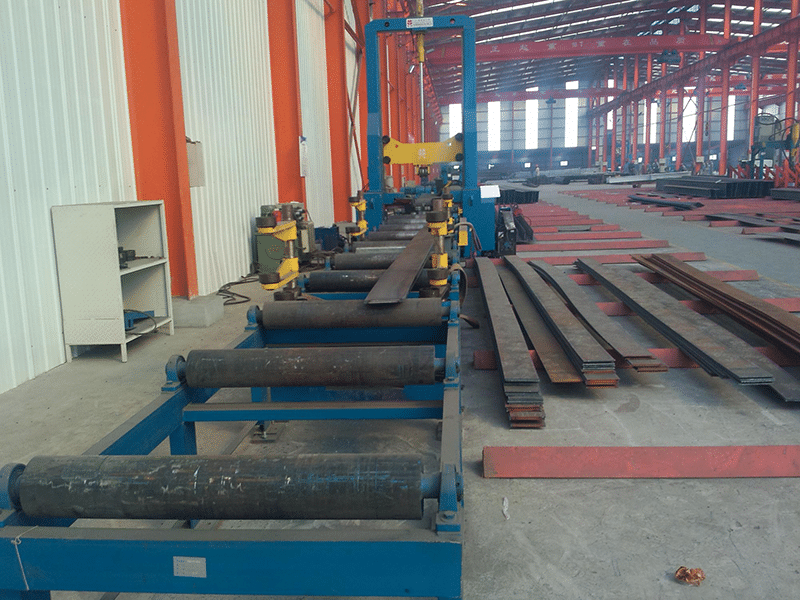

Step 2 Formation

Fixing the flange plates and the web.The gap between the flange plate and the web must not exceed 1.0mm.

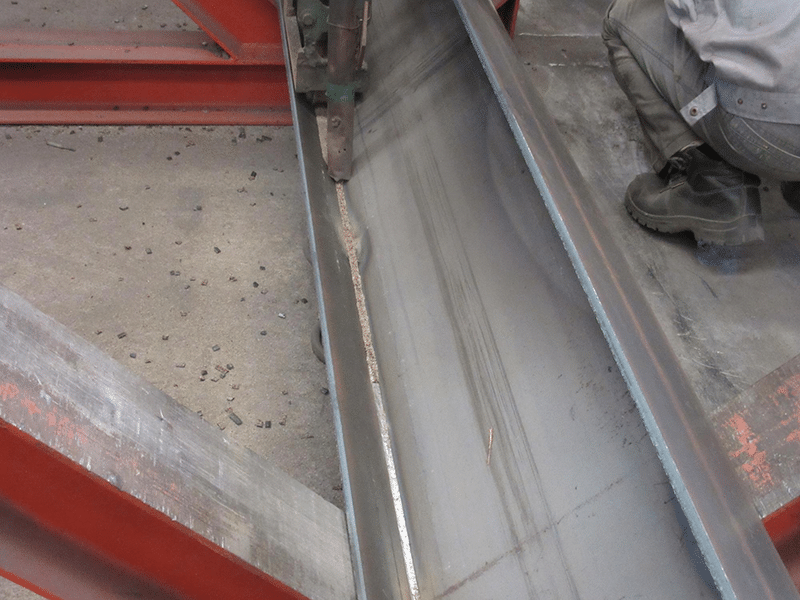

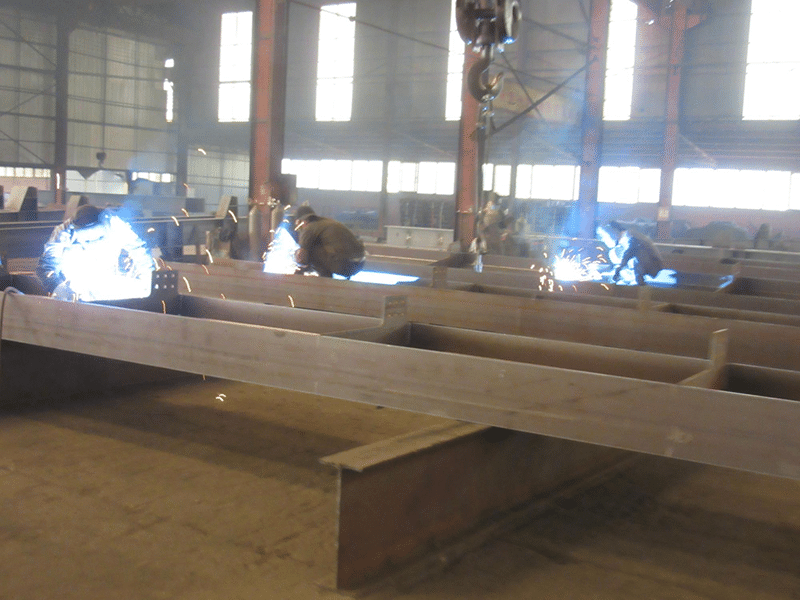

Step 3 Sybmerged Arc Welding

Welding the flange plates and the web. The welding seam surface must be smooth without any holes and slags.

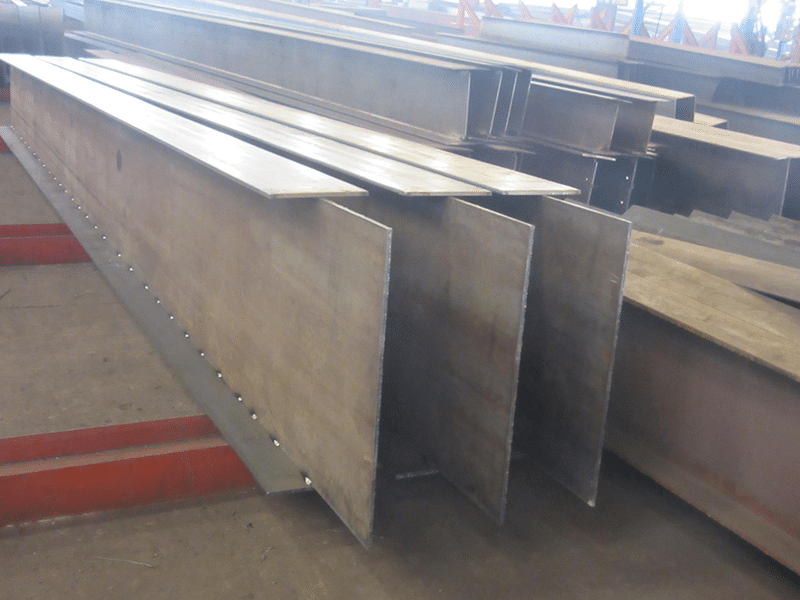

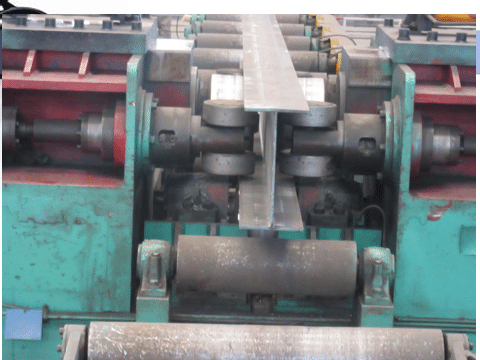

Step 4 Correcting

There will be greater welding deformation after welding the flange plates and web together, and also deviation of the squareness. Therefore, it is necessary to correct the welded H-steel by straightener.

Step 5 Drilling

After drilling, burrs must be cleaned up without damaging the base metal. If the deviation of the hole distance is beyond the specified scope, the quality of electrode must be as same as the base metal. Drill again after polishing smooth.

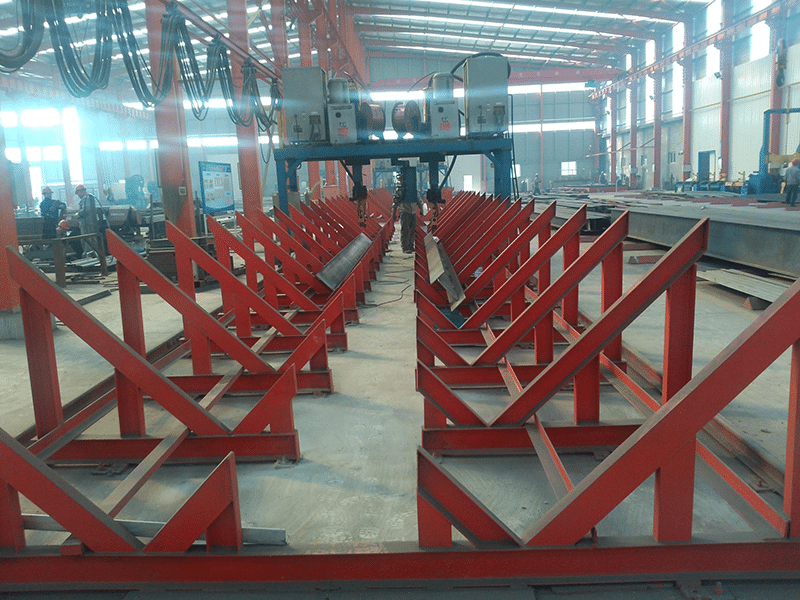

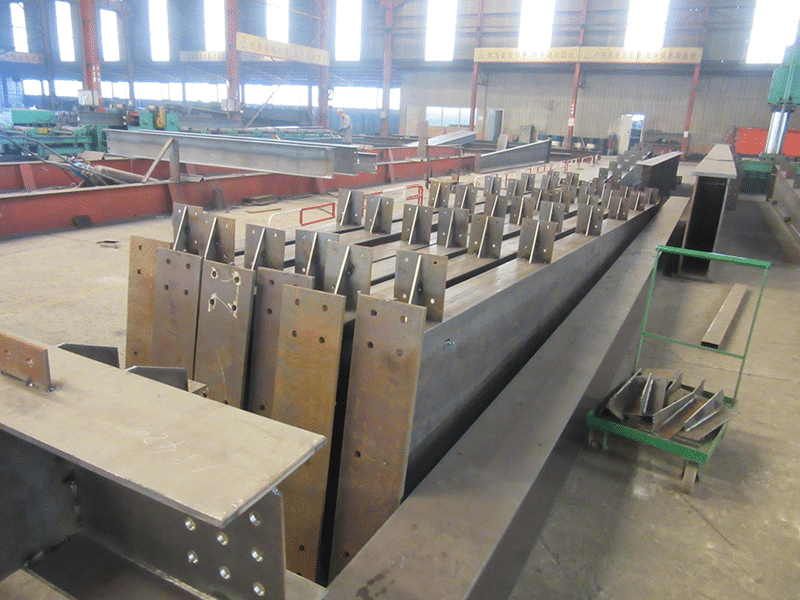

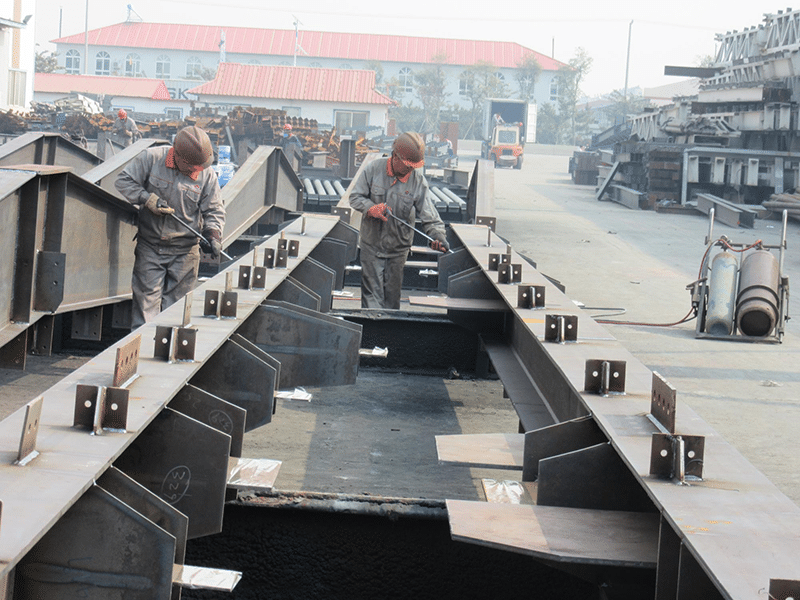

Step 6 Assembling

Strictly follow the drawing to assemble and consider the pre-welding shrinkage according to the characteristics of steel components. Then,continue processing after confirming without any error.

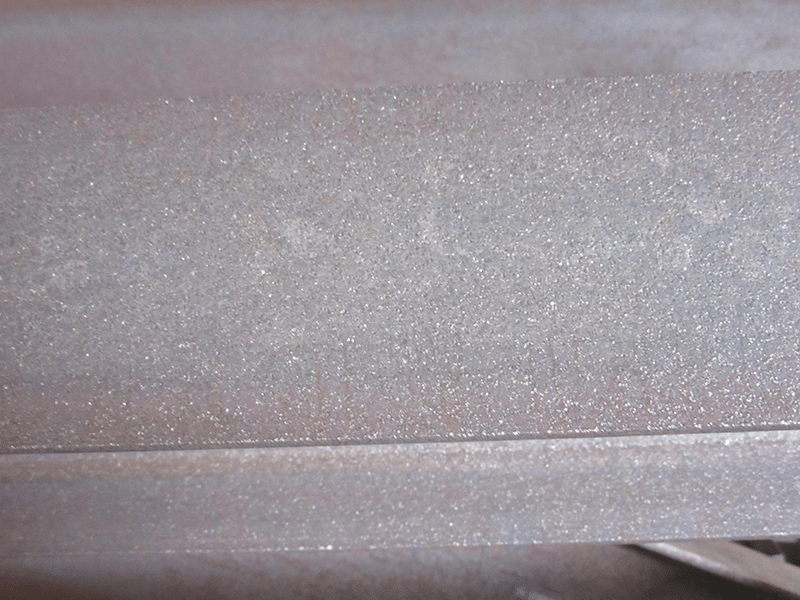

Step 8 Shot Blasting

By shot blasting, the surface roughness will be gained, which can increase the adhesion of paint film and imporve the surface quality of paint and preservative effect.

Packaging Details

The surface of each sandwich panel is covered with plastic film.

Or as required

Normally is 40’ HQ container for shipping.If you have specifical requirements,40GP and 20GP container are ok.

Port

Qingdao port,China.

Or other ports as required.

Delivery time

30-45 days after deposit or L/C received. Pls disscuss with us to decide it.