Understanding the Connection Methods of Steel Structures

Steel construction is known for its durability, strength and versatility. They are ideal for creating large structures such as bridges, buildings, and even offshore oil rigs. However, joining steel structures requires detailed knowledge of the various joining methods available. This article will detail some of the most common steel structure joining methods and how to join them.

Bolted

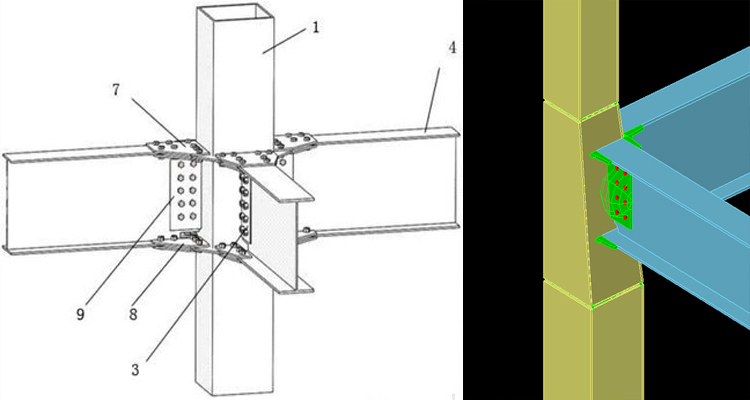

Bolt connection is one of the most traditional and commonly used steel structure connection methods. They involve joining two pieces of steel together using high-strength bolts and nuts. Bolted connections are commonly used in the construction of small and large structures.

One of the main advantages of bolted connections is that they are quick and easy to use. They are also very flexible and can be easily adjusted or modified as needed. However, bolted connections require careful installation to ensure they are strong and able to withstand the stresses placed on them.

Solder connection

Welded connections are another popular method of joining steel structures. They involve fusing two pieces of steel together using heat and pressure. Welded connections are commonly used in the construction of large structures requiring tremendous strength and durability.

One of the main advantages of soldered connections is that they are extremely strong. They are also very cost-effective and require minimal maintenance. However, welded connections are not as flexible as bolted connections and are difficult to modify or adjust once in place.

Rivet connection

Rivet connections are an older method of joining steel structures that were once popular but have since fallen out of use. Riveting involves using a rivet gun to insert a small metal rod into two pieces of steel to hold them together. Riveted connections can be very strong and long-lasting, but they are difficult to install and are not usually used in modern construction.

Adhesive connection

Bonding involves bonding the two pieces of steel together using a special epoxy glue. Adhesive connections are often used where the structure cannot be disassembled or where other methods of connection are not feasible. However, bonded joints are not as strong as welded or bolted joints and require very careful planning and execution.

Generally speaking, there are many ways to connect steel structures, each with its own advantages and disadvantages. The method used will depend on the specific needs of the structure and the materials used. Some common factors to consider when choosing a connection method include the load-bearing capacity of the structure, the size and shape of the steel used, and available access and equipment.

In the final analysis, the key to the success of steel structure connection is to understand the specific needs of the project and choose the appropriate connection method. Whether bolted, welded, riveted or adhesive, each joining method has its own unique advantages and disadvantages. By taking the time to understand and plan for a structure's specific needs, it is possible to create durable and long-lasting steel structures that stand the test of time.

Post time: May-12-2023