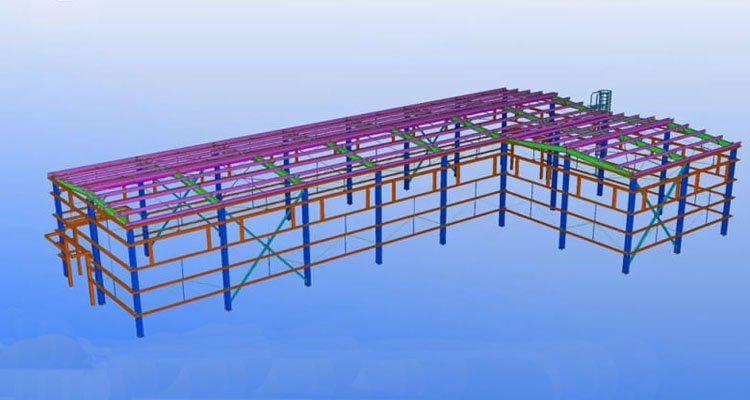

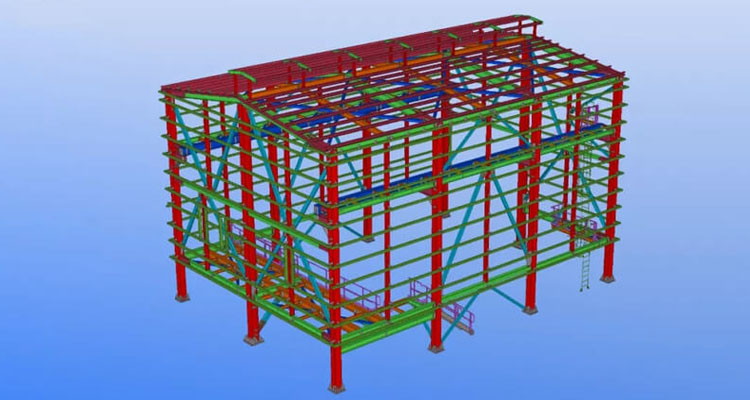

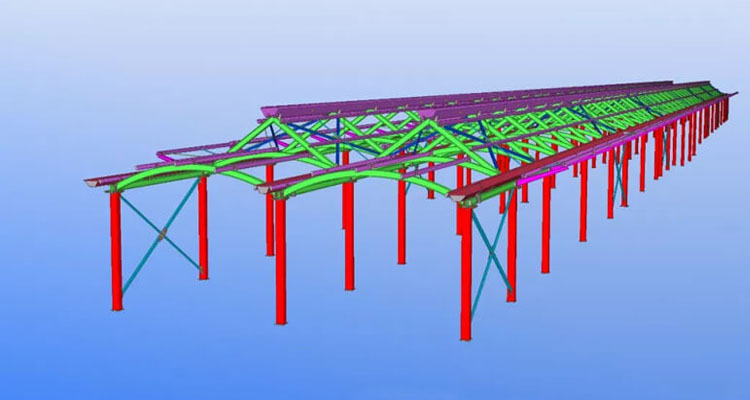

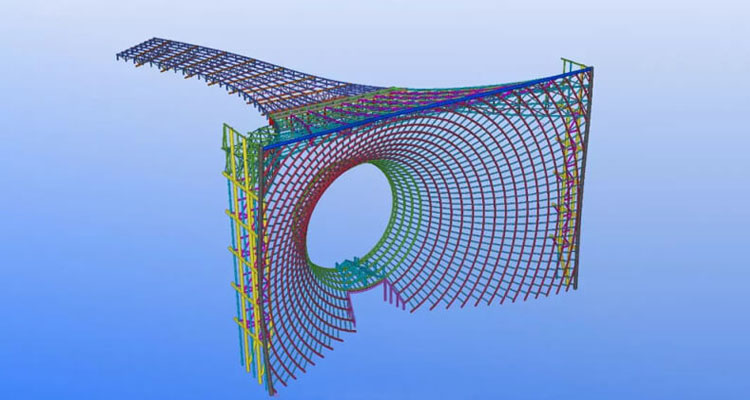

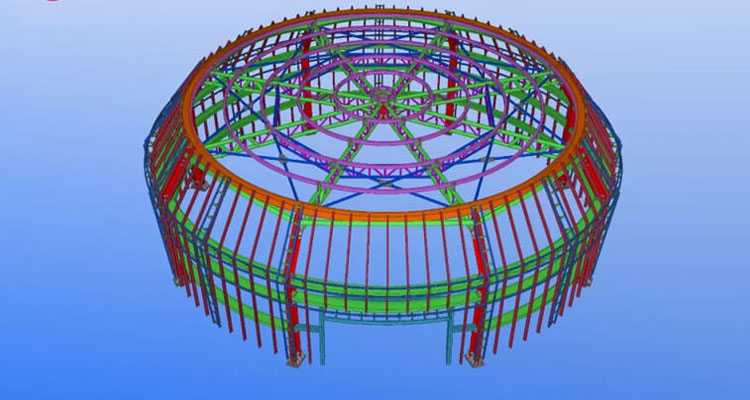

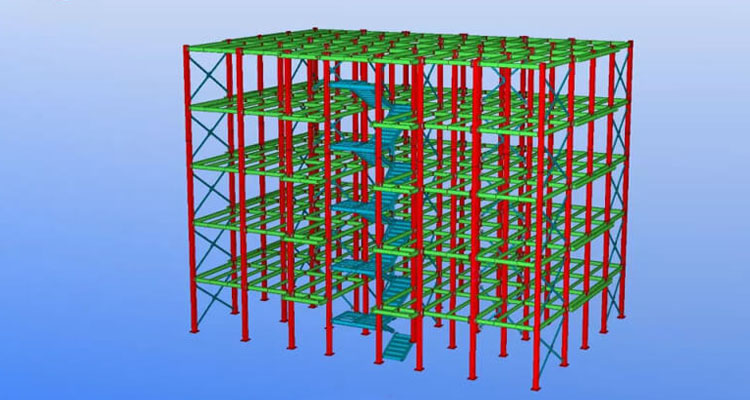

Steel Structure Tekla 3D Model Show

In recent years, the construction industry has undergone major transformations with the advent of advanced technologies. One of these innovations has revolutionized the way structures are designed, analyzed and manufactured, the use of Tekla 3D models to build steel structures. This powerful software paves the way for more accurate, efficient and cost-effective construction processes.

Tekla Structures is a comprehensive Building Information Modeling (BIM) software that allows architects, engineers and contractors to create detailed 3D models of steel structures. It has numerous advantages that make it an invaluable tool in the construction industry. Let's explore how the integration of steel structures and Tekla 3D models can reshape the way we build.

Accuracy and Precision:

One of the main advantages of Tekla 3D models is the ability to provide an accurate representation of steel structures. The software takes into account various factors such as material properties, structural connections and load distribution when creating detailed models. This level of precision helps eliminate errors and reduces the potential for costly rework during construction.

Efficient design and analysis:

Tekla Structures enables engineers and architects to collaboratively design and analyze steel structures. The software simplifies the design process by automatically generating 2D and 3D models from initial sketches, minimizing the time and effort required. Additionally, the software's advanced analysis tools help assess the structural integrity of designs by simulating real-world scenarios and assessing the effects of different loads and forces on the structure.

Enhance communication and collaboration:

Tekla 3D models facilitate better communication and collaboration among project stakeholders. The software makes it easy to share and visualize design models, ensuring everyone involved has a clear understanding of project requirements. Contractors and manufacturers can generate accurate bills of materials and cost estimates, facilitating better project planning and coordination. This enhanced collaboration can increase efficiency and reduce construction delays.

Save costs and time:

The integration of the steel structure and the Tekla 3D model resulted in significant cost and time savings throughout the construction process. Accurate models generated by the software help optimize material usage and minimize waste. In addition, the software's conflict detection feature helps identify and resolve design conflicts early, reducing costly revisions later in the project. These time and cost savings translate into more profitable projects and higher client satisfaction.

Improved item visualization:

Traditional 2D drawings often cannot provide a comprehensive visual representation of complex steel structures. Tekla 3D models address this limitation by providing a realistic and detailed visualization of the final product. Clients, architects and engineers can explore structures from different perspectives to make better decisions and ensure projects meet client expectations.

Integration with manufacturing and construction:

Tekla Structures plays a vital role in linking the design process with fabrication and construction. The software produces accurate shop drawings detailing the size, quantity and requirements of each steel component. These detailed manufacturing drawings contribute to an error-free and efficient manufacturing process. Additionally, the software's compatibility with computer numerical control (CNC) machines allows direct transfer of design data, further increasing manufacturing precision.

Post time: Aug-15-2023