How to optimize the design of portal frame?

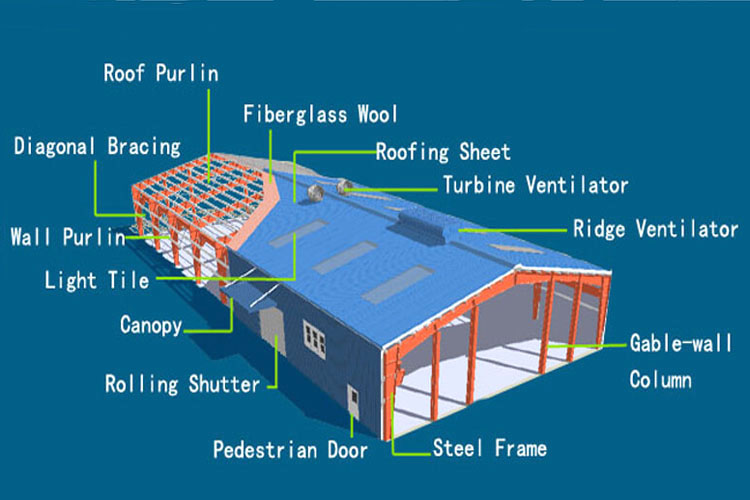

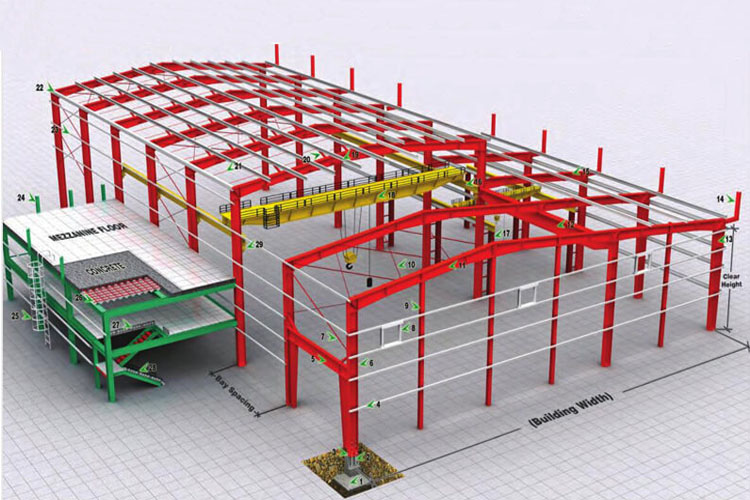

Steel portal frames are widely used in the construction industry for their strength, durability and cost-effectiveness. However, its design must be optimized to ensure maximum strength and safety while minimizing material usage and construction time. This article discusses some of the key aspects to consider when optimizing a portal steel frame design.

1. Determine the load and design standards:

Before starting the design process, it is critical to determine the loads that the portal frame will withstand. These loads may include dead loads (the weight of the structure itself and any permanent fixtures), live loads (loads imposed by people, furniture, vehicles), wind loads, and earthquake loads. By knowing expected loads, designers can determine appropriate design criteria such as deflection limits, strength requirements, and stability considerations.

2. Select the appropriate frame system:

The choice of framing system greatly affects the performance and optimization of steel portal frames. Two common types of framing systems used are rigid framing systems and braced framing systems. Rigid framing systems provide stability through moment-resistant connections, while bracing framing systems rely on the use of bracing elements. The choice of framing system depends on a variety of factors, including building function, building requirements, and ease of construction.

3. Utilize advanced analysis and design tools to:

To optimize the design of portal steel frames, advanced analysis and design tools are recommended. Computer-aided design (CAD) software and structural analysis programs can perform complex calculations, simulate different loading scenarios and generate accurate design output. These tools help designers optimize member sizes, connection details, and overall frame geometry for efficient and cost-effective designs.

4. Optimizing rod size and section:

The size and section of the steel members significantly affect the overall performance of the portal frame. By optimizing member dimensions, designers can achieve desired strength and stability while reducing material usage. The use of high-strength steel and efficient profile shapes also contributes to material optimization. However, manufacturing and structural constraints must be considered when selecting member sizes and profiles.

5. Optimize connection design:

Connections between steel members play a vital role in distributing loads and ensuring structural integrity. Optimizing connection design includes selecting the appropriate connection type, sizing bolts or welds, and providing adequate reinforcement. Advanced connection systems, such as moment-resistant connections, can improve structural performance and reduce the number of connections required. Careful attention should be paid to connection details to ensure ease of fabrication and installation.

6. Consider constructability and installation constraints:

During optimization, it is critical to consider constructability and installation constraints. Designs should be functional and capable of being built within the time and budget available. Considering standard dimensions, fabrication methods, and shipping constraints can help simplify the construction process. Collaboration between designers, engineers, and manufacturers is critical to ensuring that designs are realized efficiently and effectively.

7. Perform structural analysis and testing:

To confirm the integrity of the design and optimize its performance, structural analysis and testing should be performed. Finite element analysis (FEA) and physical testing can provide valuable insight into how a mast will perform under different loading conditions. By analyzing the results, designers can identify potential weaknesses, optimize critical areas, and ensure compliance with relevant design codes and standards.

Optimizing the design of portal steel frames involves a variety of considerations, including load determination, frame system selection, use of advanced analysis tools, member size optimization, connection design, constructability constraints, and structural analysis. By carefully addressing these issues, designers can create efficient and cost-effective portal frames that meet required strength and safety standards while minimizing material use and construction time.

Post time: Aug-12-2023