How to install a gutter for steel structure building?

Materials and application

1. Material:

At present, there are three commonly used gutter materials: steel plate gutter with plate thickness of 3 ~ 6mm, stainless steel gutter with thickness of 0.8 ~ 1.2mm and color steel gutter with thickness of 0.6mm.

2. Application:

Steel plate gutter and stainless steel gutter can be applied to most projects. Among them, stainless steel gutter is commonly used in coastal areas and places with strong corrosive gas near the project; Color plate gutter is mainly used for external gutter of gas building and projects with small engineering area and small drainage. It is often used as external gutter.

The way to connect

★ steel plate gutter

1. Installation conditions:

Before the installation of steel plate gutter, the following conditions must be met: the main body of steel structure (beam and column) has been installed and adjusted, and all high-strength bolts have been finally screwed. For the project with parapet, the parapet column and corresponding wall beam have been installed and adjusted. The steel plate gutter has been on site. Electric welding machines and welders for welding have been in place.

2. Installation:

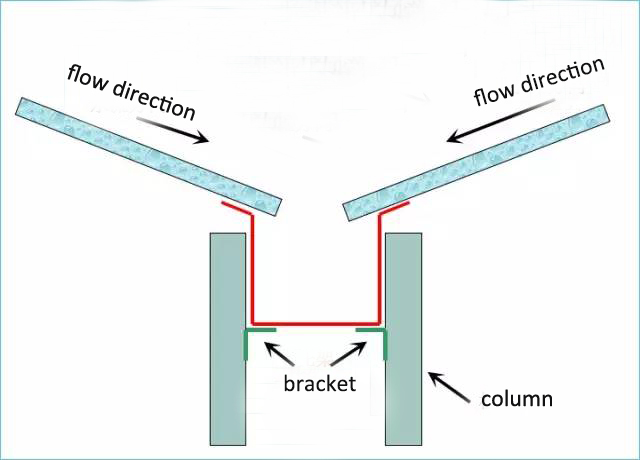

After the corresponding steel gutter is transported in place according to the design drawings, the gutter shall be transported to the designated installation area by crane or manual transportation according to the size and weight of the gutter, and the gutter shall be temporarily connected by electric welding immediately. When all the materials of a gutter are in place, draw a through line with steel wire along the outside of the gutter, and adjust the inner and outer sides of the whole gutter to the same straight line. During the adjustment, pay attention to minimize the gap at the gutter joint, and temporarily fix it with electric welding. Then fully weld the lower horizontal weld and the straight weld on both sides with a welding rod with a diameter of 3.2mm. During the welding, pay attention to the welding quality and control the welding current, Prevent burning through the gutter and increase unnecessary trouble. Intermittent welding can be used at the connection between the bottom of the gutter and the top of the column. The bottom of the gutter and the top of the steel column can be welded and fixed to increase the overall firmness. The gutter that cannot be welded on the same day can be temporarily fixed by electric welding with the above methods. If conditions permit, the gutter can also be bound and fixed with the wall beam or gutter bracket with steel wire rope.

3. Outlet opening:

The gutter outlet shall be positioned according to the design requirements. Generally, the conventional outlet shall be opened on the side of steel column or steel beam. Pay attention to the position of the support when opening the hole, and try to avoid it as far as possible, so as to reduce the amount of accessories of the downpipe. The installation method of downpipe shall be considered while opening. It is best to determine the fixing method of downpipe hoop first, so as to shorten the material of fixing hoop and reduce the cost. The hole can be opened by gas cutting or angle grinder. It is strictly prohibited to open the hole directly by electric welding. After the hole is opened, the shaft and periphery of the hole shall be trimmed with an angle grinder, and then the water outlet of the steel pipe shall be welded with the gutter. Pay attention to the welding quality during welding to prevent missing welding. After welding, the welding slag shall be cleaned in time, and the welding metal significantly higher than the gutter shall be polished with an angle grinder until it is basically flat. In order to prevent ponding at the water outlet, a sledgehammer can be used to smash down the water outlet to facilitate drainage.

4. Paint:

After all gutters are welded and inspected to be qualified, the welding slag at the welding position shall be completely cleaned again. At the same time, the paint in the welding area shall be cleaned with an iron brush, and then repaired with antirust paint of the same specification as the original paint. The gutter finish shall be painted before the roof panel construction according to the design requirements. If there are no design requirements, another layer of neoprene shall be painted on the inner side of the steel plate gutter for anti-corrosion treatment.

★ stainless steel gutter installation

1. The installation conditions and down pipe opening requirements of stainless steel gutter are the same as those of steel plate gutter.

2. Argon arc welding is adopted for stainless steel gutter welding, and stainless steel wire of the same material as the gutter is adopted as the welding rod, and the diameter can be the same as the plate thickness. Usually 1mm. Before formal welding, welders shall be organized to conduct trial welding, and batch welding can be started only after passing the test. At the same time, it is best to designate special personnel for welding, and arrange an auxiliary worker to cooperate with the operation, so as to improve the efficiency of main production. After the water outlet is welded, the area should also be properly smashed down to facilitate drainage. If there is sediment and other pollution on the stainless steel electrode, it must be removed before use.

3. Because the stainless steel gutter is processed and formed by folding, it is inevitable that there is dimensional deviation. Therefore, before the gutter is transported, it shall be comprehensively inspected to minimize the gap at the joint. Before welding, it shall be fixed by spot welding, and then welded. The bottom of the gutter shall be welded, and then the side of the gutter shall be welded. If possible, trial arrangement can be carried out, and hoisting can be carried out after numbering according to the trial arrangement, so as to minimize the welding workload and ensure the project quality. If the gap is too large to be fully welded with welding wire, it can be spliced with leftover materials. It is necessary to weld around the splice, and ensure that the welds at the edges and corners are full without missing welding.

★ Color plate gutter installation

1. The installation of mining gutter can be carried out after the installation of roof slab or at the same time with the roof slab. The details can be flexibly determined according to the site conditions.

2. The fixing of the color plate gutter is divided into two parts: one part is that the inner side of the gutter is connected with the roof panel with self tapping screws or riveted with pull rivets; the other part is that the folded edge of the outer side of the gutter is first connected with gutter brace rivets, and the other side of the brace is connected with the roof panel and purlin with self tapping screws fixing the roof panel at the crest of the roof panel. The connection between the gutter and the gutter is riveted with rivets in two rows with a spacing of 50mm according to the requirements of the company's standard atlas, The lap joint between plates shall be sealed with neutral seal. During lap joint, pay attention to the cleaning of the lap surface. After gluing, it shall stand for a short time, and the main can be moved after the glue is cured.

3. The opening of gutter outlet can be directly carried out by cutting machine, and the position shall meet the design requirements. The outlet and gutter bottom shall be fixed by pull rivets according to the requirements of relevant nodes of the standard atlas, and the treatment requirements of sealant at the connection shall be connected with the gutter.

4. The flatness requirements of the color plate gutter are the same as those of the steel plate gutter. Because it is mainly determined by the installation quality of the main structure, the construction quality of the main structure must be guaranteed before the gutter is installed, so as to lay a good foundation for the improvement of the installation quality of the gutter.

Post time: Apr-03-2022